Aqua Clean Multi

The Multi series parts cleaners are used especially in the machine working industry for cleaning and rinsing of machined components before assembly, painting and heat treating.

The machines are used when the cleanliness standards require both cleaning and rinsing, which we call a multi-stage process. There are also special versions of our Multi-series available, which are used in the aerospace/aviation and the railway, metro and tram industries.

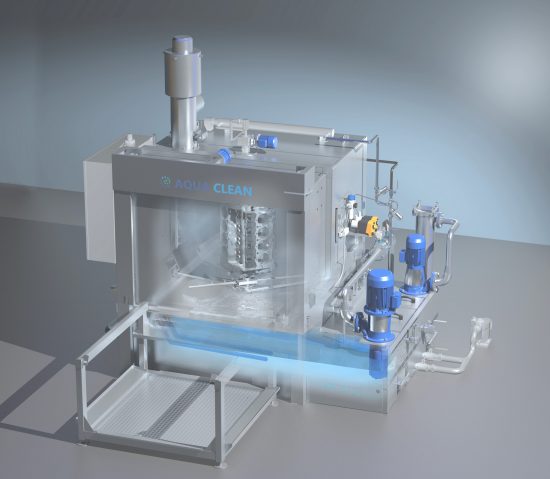

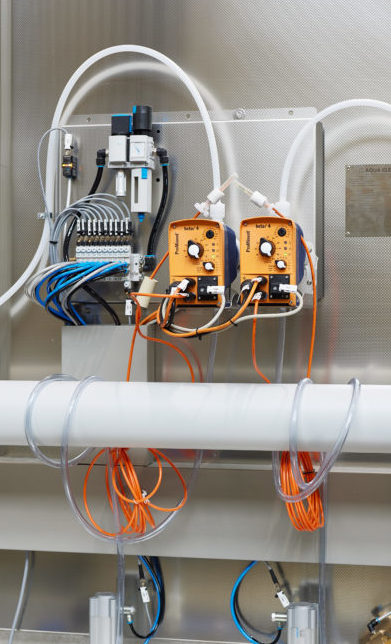

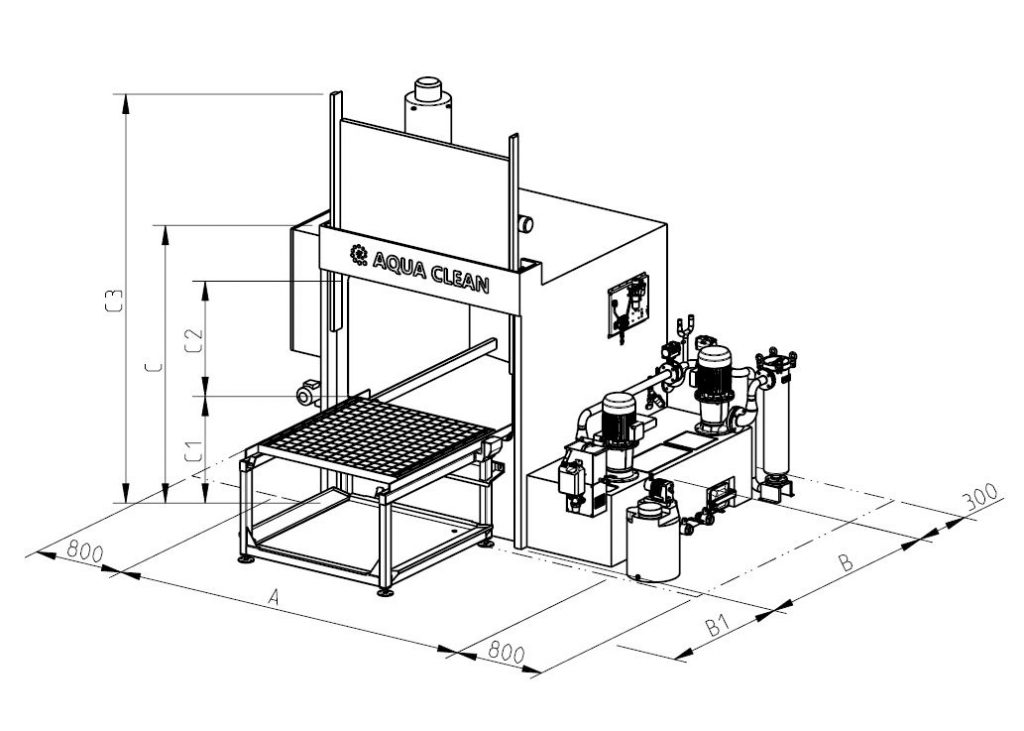

The machine is manufactured in stainless steel and consists of a heat insulated enclosed cabinet with one or two mechanically driven lifting doors, rotating spray system and a tank system with an automatic refill function. A load platform or a load trolley is placed in front of the cleaning machine for the loading and unloading phases. The machines can feature two or three liquid tanks, rinsing fixtures, drying with a fan or with cold or hot air blast, and automated transport systems.

The cleaning, degreasing and rinsing processes are carried out with a rotating spray system with built-in nozzles. The hot liquid is sprayed from all directions onto the components with a high mechanical effect. After each process, the liquid is filtered with a full-flow filter system and returned into the proper tank. The filter unit and filter baskets are located at the side of the machine, thereby making the filters easy to clean.

The machines can also be supplied with a reciprocating spray systems. Such systems are used in situations where the length of the components to be cleaned is much longer than their width.

Main benefits:

- High quality and a robust structure

- Excellent cleaning results

- High productivity

- Easy maintenance and operation

Intended for:

- Medium and large-size components

- Washing and rinsing with drying option

- Production lines